Introduction: Denim Jeans pant is renowned for being extremely trendy men's fashion item. Even without jeans, a young man can't think of a single day. It is also called denim pants because they are made from denim fabric. People also like to call it 5 pocket denim jeans pant. Because it has a total of 5 pockets; two on back, two on the front, and a little coin pocket inside the right front pocket. Denim Jeans pants used to be simply fashionable items, but nowadays people also concentrate on the comfort level of the pants.

Today in this post, we learn the Operation Breakdown of 5 Pocket Denim Jeans pant with SMV and Production Target.

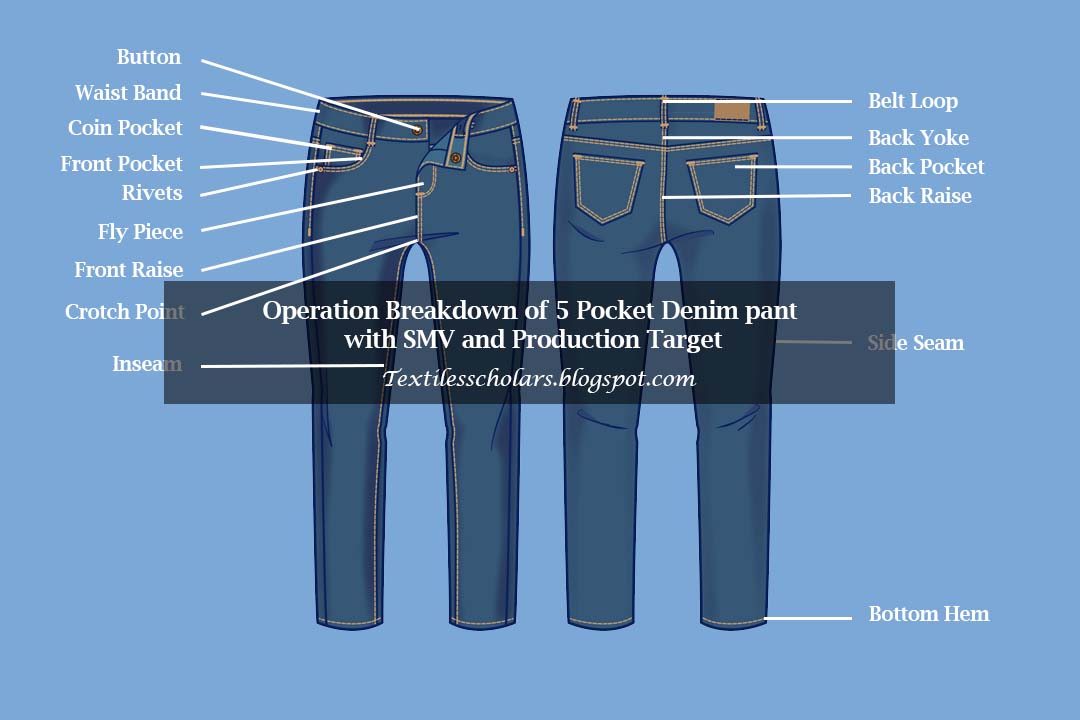

Common parts of a 5 Pocket Denim jeans pant: If we breakdown a 5 Pocket Denim jeans pant, we will find some common parts;

- Waist Band

- Belt Loop

- Button

- Fly piece

- Coin Pocket

- Front Pocket

- Back Pocket

- Jeans Rivets

- Crotch Point

- Back Yoke

- Bottom Hem

- Back Rise

- Front Rise

- Side Seam

- Inseam

- Zipper

Operation Breakdown of a 5 Pocket Denim jeans pant: Operation Breakdown of a 5 Pocket Denim jeans pant is done by the following table;

| SL. No. | Name of Operation | Cycle Time | Calculated Production at 100% Efficiency |

|---|---|---|---|

| 1 | Back Yoke Join | 0.28 | 214 |

| 2 | Back Yoke Top Stitch | 0.26 | 230 |

| 3 | Back Raise Join | 0.28 | 214 |

| 4 | Back Raise Top Stitch | 0.26 | 230 |

| 5 | Back Pocket Cut | 0.42 | 143 |

| 6 | Back Pocket Mouth Rolling | 0.40 | 150 |

| 7 | Back Pocket Stitch | 0.30 | 200 |

| 8 | Back Pocket Ironing | 0.55 | 109 |

| 9 | Back Pocket Join With Back Part | 0.57 | 105 |

| 10 | Front Raise | 0.30 | 200 |

| 11 | Front Raise Top Stitch | 0.28 | 214 |

| 12 | Fly Pieces Stitch | 0.32 | 188 |

| 13 | Zipper Stitch With Fly Piece | 0.30 | 200 |

| 14 | Fly Piece Back Attaching | 0.28 | 214 |

| 15 | Fly Piece Front Attaching | 0.30 | 200 |

| 16 | Front Pocket Mouth Rolling With Piping | 0.52 | 115 |

| 17 | Front Pocket Horizontal And Vertical Tack | 0.45 | 133 |

| 18 | Front Pocket Bag Stitch And Inside Out | 0.30 | 200 |

| 19 | Front Pocket Bag Top Stitch | 0.36 | 167 |

| 20 | Front And Back Part Matching | 0.28 | 214 |

| 21 | Inseam Join | 0.50 | 120 |

| 22 | Inseam Top Stitch | 0.55 | 109 |

| 23 | Side Seam Join | 0.62 | 97 |

| 24 | Safety Stitch | 0.60 | 100 |

| 25 | Side Cord Stitch | 0.45 | 133 |

| 26 | Care Label Attaching | 0.28 | 214 |

| 27 | Loop Measure, Cut And Attach | 0.30 | 200 |

| 28 | Waistband Mark | 0.30 | 200 |

| 29 | Waistband Match | 0.30 | 200 |

| 30 | Waistband Join | 0.57 | 105 |

| 31 | Waistband Mouth Cut | 0.30 | 200 |

| 32 | Waistband Mouth Close Inside | 0.71 | 85 |

| 33 | Loop Tack Down | 0.28 | 214 |

| 34 | Loop Tack Top | 0.28 | 214 |

| 35 | Turn Body And Thread Cut | 0.30 | 214 |

| 36 | Bottom Hem Join | 0.58 | 103 |

| 37 | Loop Stitch | 0.45 | 133 |

| 38 | Back Pocket Tack | 0.30 | 200 |

| 39 | Front Pocket Tack | 0.32 | 188 |

| 40 | Eyelet Hole Creating | 0.18 | 333 |

| 41 | Flap Mark | 0.25 | 240 |

| 42 | Reveat Attaching | 0.32 | 188 |

| 43 | Waist Hole Creating | 0.20 | 300 |

| 44 | Waist Button Attach | 0.20 | 300 |

| 45 | Final Thread Cut | 0.40 | 150 |

| Total Cycle Time | 15.73 |

Table - 1: Operation Breakdown of 5 Pocket Denim jeans pant.

From the above table, we get operation breakdown and total cycle time. We also estimate each operation production target which helps us line balancing and preparing machine layout.

You may like: Operation Bulletin of 5 Pocket Denim Jeans pant with Machine Layout Plan.

SMV calculation of a 5 Pocket Denim jeans pant:

Problem: From the above table, we find total cycle time is 15.73 minute, suppose the performance rating of all operator is 80% for Denim jeans pant. Now, Find out the SMV for that Denim jeans pant.

Solution:

We know,

SMV = Basic time + Allowance

= (Cycle time × Rating) + (Bundle allowances + machine and personal allowances)

= (15.73× 0.80) + (Bundle allowances + machine and personal allowances)

= 12.30 + ( 12.30 × 10%)+ (12.30× 20%)

= 12.30+ 1.23 + 2.46

= 15.99

So, we find out SMV for that Denim jeans pant is 15.99 minute.

Production target calculation of a Denim jeans pant:

Problem: We find SMV for that 5 Pocket Denim jeans pant is 15.99 minute. Suppose, No. of worker of that line is 64, the efficiency of that line 80%. Find out the production target per day of that 5 Pocket Denim jeans pant in one sewing line.

Solution:

Here,

SMV = 15.99 Minute.

No. of worker = 64.

Line efficiency = 80% = 0.80

We know, Total working hour in a day = 8 hr.

Now,

Production Target = {(Total manpower per line × Total working min per day )/ S.M.V.} × Efficiency

= { (64 × 8 × 60) / 15.99 } × 0.80

= 1536.96~ 1537

= 1537 pieces.

So, Daily production target = 1537 pieces in one sewing line

and Hourly production target = 1537 / 8

= 192.125~ 192 pieces / hr.

= 192 Pieces/hr in one sewing line.

= 192 Pieces/hr in one sewing line.

So, From this post, we learn about Operation breakdown of a 5 Pocket Denim jeans pant, Total Cycle Time, SMV calculation, and Production target in daily and hourly.

Thank you for your patient reading. Is the article helpful? Please, share this article with others.

Operation Breakdown of 5 Pocket Denim pant with SMV and Production Target

Reviewed by Mustaqim-Ul-Alam

on

August 22, 2019

Rating:

Reviewed by Mustaqim-Ul-Alam

on

August 22, 2019

Rating:

Reviewed by Mustaqim-Ul-Alam

on

August 22, 2019

Rating:

Reviewed by Mustaqim-Ul-Alam

on

August 22, 2019

Rating: